Efficient Color Management with Plate Compensation Curve

Release Time:

12 May,2025

With the development and application of printing technologies and printing equipment such as CTP technology and digital proofing technology, the role of color management in printing production has become increasingly important. More and more printing companies have begun to implement color management based on G7 technology, hoping to form a more efficient printing production system through the cooperation of color management based on G7 technology and modern printing new technology to improve printing quality and corporate competitiveness.

With the development and application of printing technologies and printing equipment such as CTP technology and digital proofing technology, the role of color management in printing production has become increasingly important. More and more printing companies have begun to implement color management based on G7 technology, hoping to form a more efficient printing production system through the cooperation of color management based on G7 technology and modern printing new technology to improve printing quality and corporate competitiveness.

This article mainly discusses how to ensure the stability of CTP plate making and various printing links in the printing production process by adjusting the color management method of the printing plate making compensation curve, establish control standards for the printing production process, and ensure the high quality and high reliability of the printed products.

Guided by ISO 12647, the G7 process method is used to measure the printing quality control parameters such as density, dot increase, gray balance, and color of the printing sample. Through these parameter analysis, various technical parameters that ensure stable printing plate output and stable printing conditions are obtained, and a normal production environment with good stability and repeatability of printing products is obtained, and a printing plate making compensation curve based on these parameters is generated. Among them, the color management calibration process is based on the G7 process.

Color management equipment and environment preparation before printing

Before printing calibration samples, you must ensure that both the CTP plate making machine and the printing machine are in an optimal and stable production state. The CTP plate making machine needs to clean the laser head and replace the development potion to ensure the regular shape of the plate making dots and the linearization and stability of the plate. The printing press needs to calibrate the pressure of the ink roller and the pressure between each roller in advance to make it meet the recommended equipment standards; measure and ensure the elastic hardness of the ink roller and rubber cloth; measure and calibrate the grinding pressure of each junction tooth row; measure and adjust the chemical environment of the moisturizer to ensure the regular, full and stable shape of the printing dots. At the same time, the temperature and humidity of the workshop are controlled so that the temperature of the workshop is controlled at 23-26℃ and the humidity is controlled at 50%-60%. The field chromaticity values of the CMYK ink used on the test paper (128g/m2 double copper) were measured to ensure compliance with the standards in Table 1.

The state of the printing press is detected and controlled by printing the flat screen test plate shown in Figure 2. During printing, the horizontal density of each color sheet is printed according to the G7 density standard according to the actual color blocks, as shown in Table 2. Then the longitudinal density of the printing sheet is measured to confirm the circumferential uniformity of the printing machine, and through multiple tests and adjustments, it reaches the optimal printing state.

Table 2 Recommended standards for printing field density in CY/T5

Printing and sampling process after equipment calibration

The recommended color sequence of the G7 process is KCMY, and the color temperature environment is D50 (i.e., the color temperature is 5000K). It is generally printed according to the recommended color sequence. Since the focus of G7 gray balance observation is on the gray scale, the overprinting requirements for three colors are relatively high, and special attention should be paid to overprinting. At the same time, we should also measure the ground color blocks more so that the ground density of each color can be maintained within the recommended density of the industry standard, and the comprehensive color difference between the ground color value and the industry standard color value of each color is less than 1. During the printing process, it is also necessary to observe whether the printing press is operating normally and stably, especially the ink and wash balance state. During the printing process, the Lab values of the neutral gray (HR-cmy) and 50K (HR-k) color blocks of CMY are also required to measure the Lab values of the neutral gray (HR-k) color blocks many times to ensure that they are basically consistent.

According to the stability requirements of the G7 process, the testing and calibration of the printing press requires about 3,000 to 6,000 sheets of paper, so the sample sheet needs to be drawn after printing 2,000 sheets at a stable speed.

Printing sampling measurement process

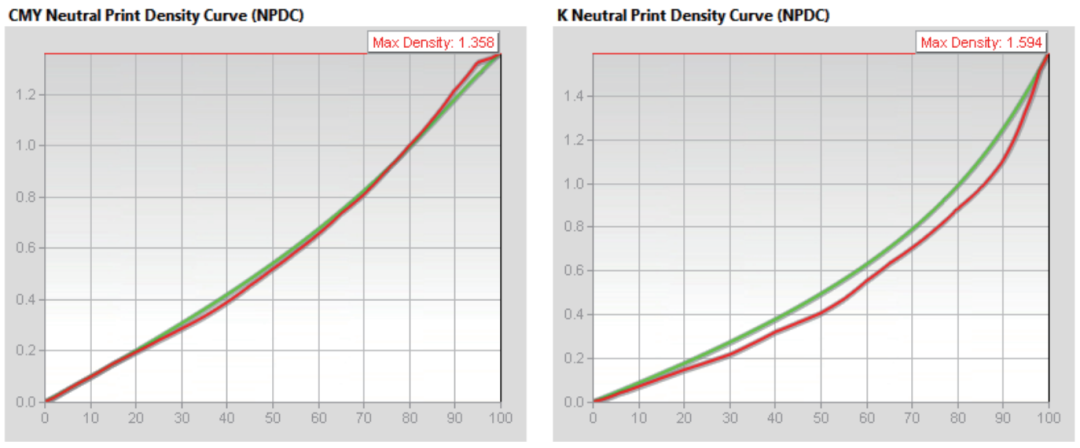

After the sample sample is dried, the relative dot increase values of the monochrome black and trichrome overprinted black gray scales on the P2P color scale are measured respectively. The fourth column of P2P is the three-color gray balance and the fifth column is the monochrome gray balance. In order to eliminate errors, measure two sets of color scales that are inverted on the left and right sides of the layout, and take the average value of the measurement results; or select multiple sample measurement color scales to get the average value. Measurements can be measured manually, or they can be measured using surveying and mapping software such as IDEAlink curve drawing software. The measurement results are drawn on the coordinate axis into an NPDC curve as shown in Figure 3 and compared with the preset G7 standard curve.

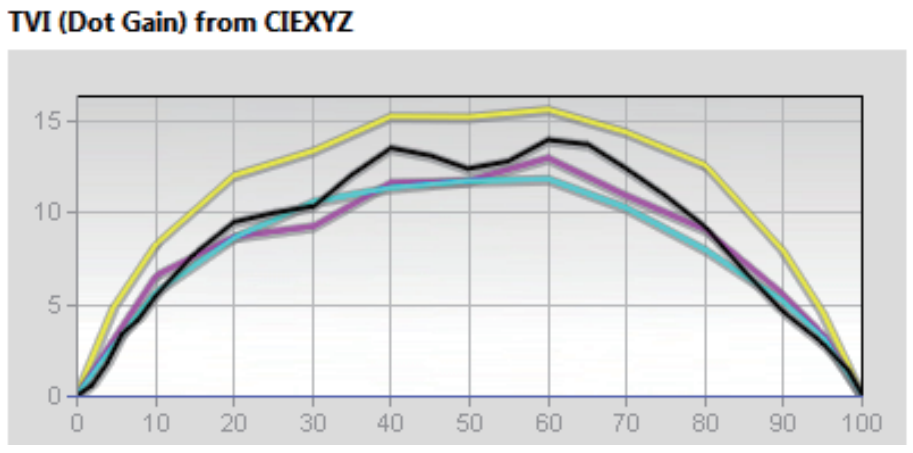

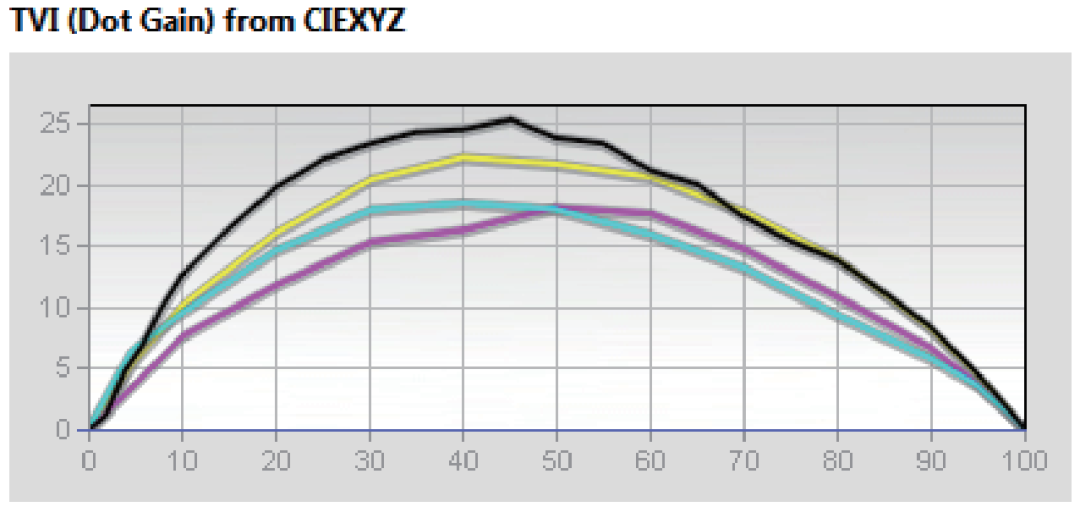

At the same time, the dot enlargement curve (TVI curve) of the sample sample was measured and the observation was recorded. As shown in Figure 4, before NPDC curve correction is performed, the ink characteristics of Y ink cause its dot to increase significantly than the other three colors.

Printing plate making compensation curve correction

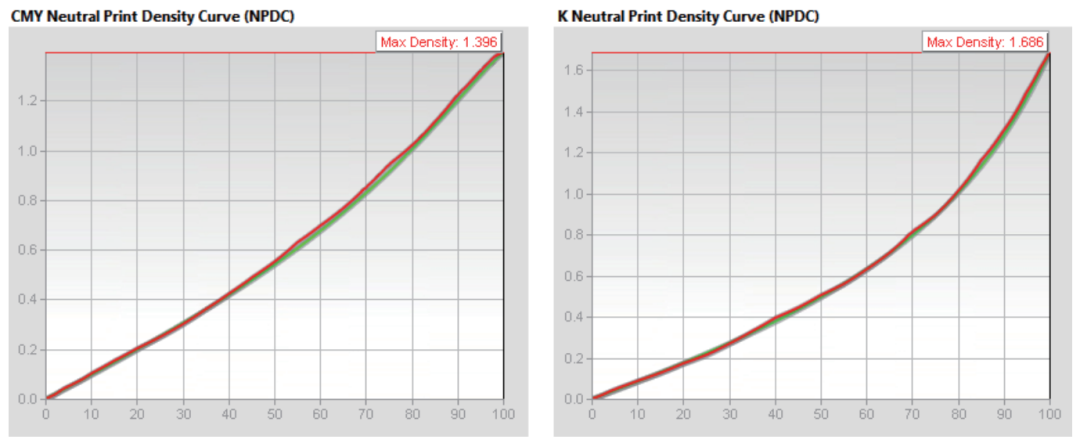

According to the key inflection points of the actual measurement curve and the preset curve on the surveyed and mapped NPDC curve, the existing printing plate making compensation curves within the inflection point range are adjusted and corrected. A new compensation target value is obtained based on the difference between the intersection point of the horizontal and vertical axis and the NPDC curve and input it into the printing plate-making compensation curve. Then, based on the corrected printing plate making compensation curve, a new set of G7 basic test plate plate plate plate plate plate plate plate plate plate plate plate plate plate plate plate plate calculation curve, and data verification is carried out again according to the previous printing, sampling and measurement methods to observe whether the NPDC curve has achieved the expected target. The measurement results are shown in Figure 5.

At the same time, the dot enlargement curve (TVI curve) of the sample was measured, and the observation was recorded as shown in Figure 6, and compared with the TVI curve before correction. After NPDC curve correction, the gray balance control of the G7 process will make the K density greater than the K density of the traditional density control method, and the increase in K outlets will be greater than the other three colors.

Since the G7 process pays more attention to gray balance than the TVI curve and the field density, when the gray balance does not exceed the tolerance range, the TVI curve can be adjusted without adjusting it. The measurement data of the TVI curve is mainly based on observation reference.

Related News

Add: No. 30-45 Huixi Road, Liangxi District, Wuxi, China

Follow us